Stainless Steel Electropolishing in Wisconsin

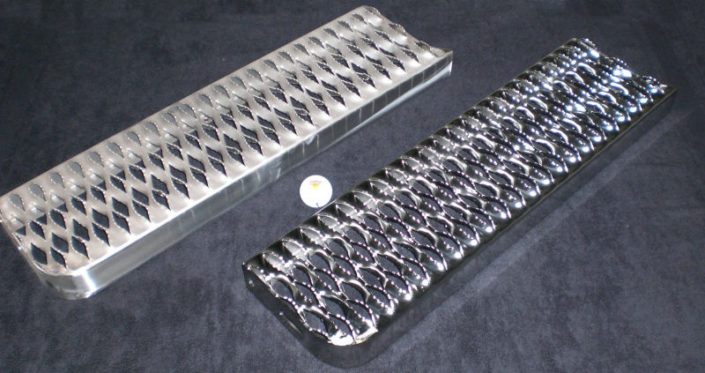

Electropolishing of Stainless Steel – An electrochemical process whereby stainless steel parts are attached to an electrically conductive holding rack and immersed in an acid electrolyte bath. Electric current is passed through the part and surface atoms are drawn from the part to a cathode. The end result is a micro smoothing of the surface and a brightening and shining of the surface. The longer the parts are exposed to the current, the more surface material is removed.

Process Description – Parts to be polished are hung on an electrically conductive rack, immersed in an acid electrolyte, and direct current is passed through the parts. Surface atoms on the parts are attracted to cathodes in the tank which results in a shining and micro-smoothing of the parts. The process is cost advantageous because typically multiple parts can be polished at the same time, reducing the cost per piece.

Capabilities

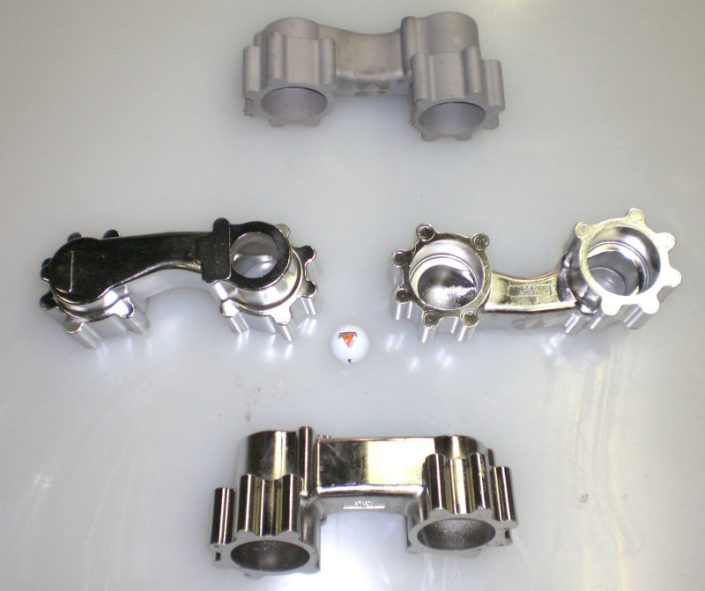

We currently are capable of electropolishing all alloys of stainless steel. Size capability ranges from small parts like nuts, bolts, and washers up through parts 9 feet in length. With special tooling, internal areas of parts can also be polished.

Reference Standards

- ASTM B912 – Standard Specification for Passivation of Stainless Steel Using Electropolishing

- Good and accepted industry practices